TPE is a compound of rubber and polypropylene, developed as a cost effective way to waterproof and protect drainage holes and outlets on roofs and balconies in conjunction with bituminous waterproofing membranes. The material is tough, flexible and durable.

These outlets, collars and vents are ideal for SBS and APP bituminous membranes, including built-up (felt), mastic asphalt, hot melt and other liquid applied membranes such as Fibreglass.

The resilient TPE material is UV stable and resistant to deterioration by normal atmospheric elements and ground salts. It can withstand temperature of 120°C and will not become brittle at very low temperatures.

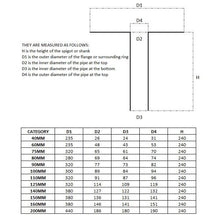

The circular drain connector is used for downpipes and outlets on a roof or terrace within the main body of the concrete deck. Made from TPE, these outlets are for use where a circular hole is cast into the concrete deck. The area is fully waterproofed around the hole and into the hole with a first layer / coat of membrane. The connector is then inserted into the hole, and a second coat / layer of membrane is installed on top of the flap (flange).

The connectors are manufactured with a perforated flange so the membrane oozes through to bond to itself in a sandwich situation, ensuring a very secure bond. The shank s 240mm long and is designed to fit inside an HDPE pipe tightly.

The shank or pipe is manufactured to a slight cone shape, making it easier to press into the hole and helping to prevent the connector rising out of the hole. There are two rings on the shank which help to ensure that as it is pressed into the hole no water can pass back up the pipe, acting as a further drain trap. At the mouth of the shank there are a series of ribs and serrations along the inside, which ensure a leaf guard or gravel-excluder can be fitted into the connector securely.

The connector should not come into direct contact with the bare concrete, as this risks the chance of water passing beneath the rubber profile and ingressing into the structure. The connector sits between two layers of waterproofing. For two coat liquid applied membranes this can be achieved fairly easily without disrupting the waterproofing process.

For sheet membranes the best practice is that an additional layer of membrane should be applied and adhered to the area. The first layer can be installed and fully bonded, the outlet is inserted into the hole, then a patch of membrane is fitted above and around the outlet. It should be fully bonded to the flange of the outlet and the first layer of membrane by adhesive or heat-bonding to achieve a fully watertight bond.

TPE - for use with bituminous felts & asphalt.

Flange with holes - perforated.

Height : 240mm.