Leister UNIROOF 300 Automatic Roof Welding Machine 110V 1800W 168.635

The all new UNIROOF 300 automatic roof welding machine is the one of the most advanced machine for welding roof membrane yet developed. It is over 10% faster at welding than the previous equivalent machine, the UNIROOF ST.

Not only can the UNIROOF 300 weld roof membrane at speeds of up to 2.8m/min, it is now a fully digital machine with closed loop design to ensure parameters remain locked in ensuring consistent welds every time.

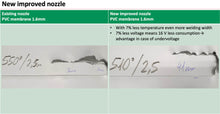

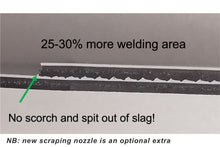

To improve the quality of the welds even further, Leister has developed a brand new patented nozzle design, the Scraping Nozzle, which will be available to purchase separately.

The new scraping nozzle (optional extra - see 170.119 under accessories & spares further down) creates a 25-30% larger surface area within the weld, a 12-16% wider weld width and produces a much stronger and more robust membrane weld with higher tear resistance and with minimal scorch and spit out of slag on PVC. Not only does the new scraping nozzle improve the physical weld quality it also allows for faster roof membrane welding speeds, lower temperatures and at a lower voltage than previously possible. The new design also virtually eliminates the need for solvents to clean the nozzle, better for productivity and for the environment.